MITUTOYO - High-Accuracy Digimatic Micrometer MDH-25MB| JSR GROUP

High-Accuracy Digimatic Micrometer MDH-25MB

MDH-25MB

Easy, Rapid and High-accuracy Measurement of Workpieces That Require an Accuracy of 1 μm or Less

Delivering a Maximum Permissible Error JMPE of ±0.5 μm accuracy at 0.1 μm resolution means Mitutoyo's MDH-25MB is the most accurate digital micrometer available*, and this instrument will enable you to easily and

rapidly measure workpieces that require very-high-accuracy measurement. This remarkable performance has been attained thanks to Mitutoyo's proprietary ABS (absolute) rotary encoder and high-accuracy thread cutting technology.

APPLICATION

Beyond the Usual Micrometer! Many More Kinds of High-accuracy Parts Now Measurable.

This micrometer allows easy, rapid and high-accuracy measurement of workpieces that require a measuring accuracy of 1 μm or less, such as medical parts, precision instruments and auto-parts regarded as difficult to be accurately measured with conventional micrometers.

|

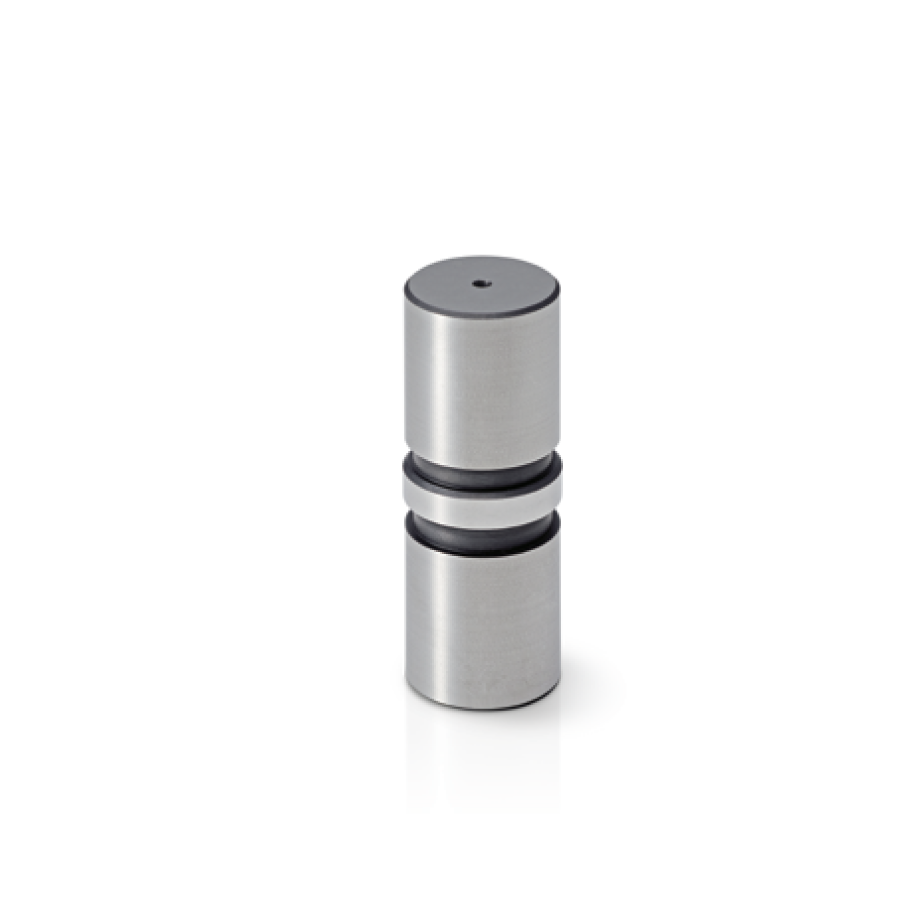

Pin gage measurement Pin gages are widely used for measurement of the diameter or center-to-center distance of holes. The periodic calibration of a high-precision pin gage requires high-accuracy measurement.

|

Hypodermic needle measurement To reduce injection pain as much as possible, the outside diameter of hypodermic needle tips has become much thinner. Some needles have a tip diameter of just 0.2 mm, thus requiring high-accuracy measurement.

|

|

Fiber optics measurement The optical-transmission cylindrical "core" made of quartz glass is 0.01 to 0.05 mm in diameter. Since its thickness is similar to a strand of hair, high accuracy is required for its measurement. |

Gap gage calibration Gap gages are widely used for easy measurement of small gaps in assemblies. |

|

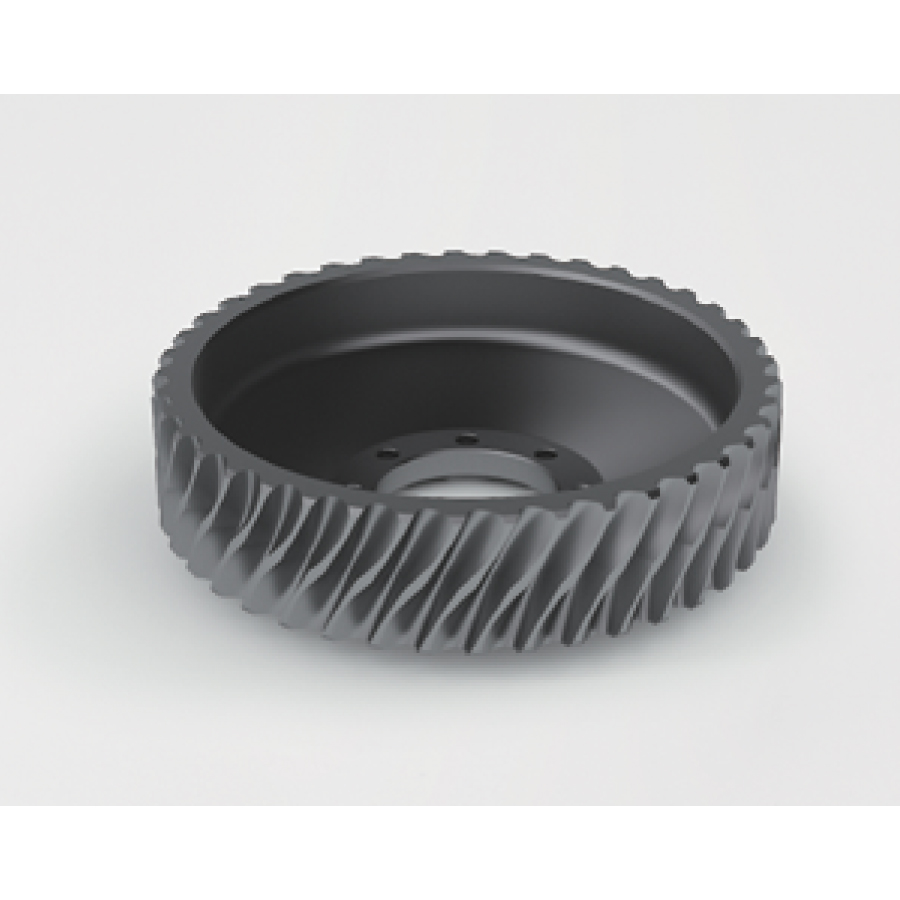

Gear tooth measurement As gears decrease in size and weight, the MDH allows for convenient high accuracy evaluation. |

Implant measurement An abutment is used for dental implants. Abutments have various lengths, angles, and materials. Each abutment needs to be made and measured very accurately. |

Catheter measurement High-accuracy measurement is needed when manufacturing the fine tubing widely used in the medical field, such as a catheter that plays a crucial part in dilating a blood vessel. |

TECHNOLOGY

|

Ratchet thimble with an anti-friction bearing Measurement repeatability has been improved by changing from sliding to rolling friction to dramatically reduce the torque needed to operate the constant-force device. This makes measurement even more consistent, even for operators new to this micrometer. |

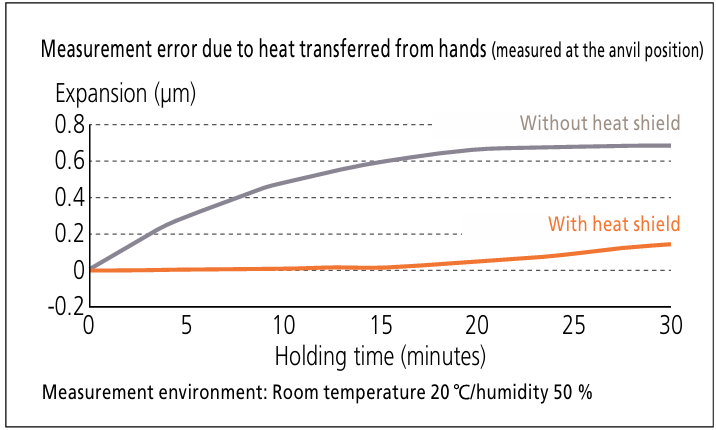

Heat transfer reduction with a heat shield The influence of heat transferred to the micrometer frame through hands has been reduced during measurement with this micrometer by fitting the supplied heat shield. The graph below shows that the heat shield almost eliminates hermally induced error by minimizing thermal expansion of the frame.

|

|

ABS (absolute) rotary encoder with a resolution of 0.1 μm and high-accuracy thread cutting technology The development of a 5000-division rotary encoder has achieved the unprecedented resolution of 0.1 μm in a hand-held micrometer.

|

USABILITY

|

Reliable operation The sound of the ratchet provides a reliable operation and repeatable measurements. Absolute encoder The ABS (absolute) rotary encoder eliminates the need for origin point setting at every power-on, allowing immediate starting of measurement. |

Wear-resistant carbide tip The ø3.2 mm carbide tip on the measuring face is highly resistant to wear, allowing accurate measurement for an extended period of time. Zero-setting function This function allows the displayed to be zero set at any position, thus facilitating comparative measurement. Also the absolute value from the origin can be restored. |

Versatile functionality enhances productivity and ease of use This micrometer is equipped with many useful and time-saving functions such as resolution switching (0.0001 mm/0.0005 mm), function lock, and presetting. Built-in "Hold" function This function can hold (freeze) the displayed value. Enables the micrometer to be removed from a workpiece when the readout is not easily viewable so that the measurement value can be read at your convenience. |

Functions

| Preset (ABS measurement system): | The measurement origin can be preset to any value within the display range for convenience in measuring. |

| Zero-setting (INC measurement system): | The display can be zeroed at any position of the spindle, making comparison measurement easier. Returning to the absolute-measurement mode is easily accomplished. |

| Hold: | The displayed value is held while the spindle is withdrawn and the micrometer moved so that the display can be read at the operator's convenience. |

| Resolution switching: | The resolution of the display can be switched. If 0.1 μm measurement is not required, the resolution can be switched to 0.5 μm. |

| Function lock: | Functions such as preset or zero-set can be locked to avoid inadvertently changing the origin position. |

| On/off: | The power can be turned off after measurement is complete.Even after the power is turned off, the origin or last zero-set position remains in the memory. |

| Auto power off: | Even if the power is left on, the power turns off automatically if the micrometer is not used within a 20-minute period. |

| Measurement data output: | Measurement data can be output, allowing easy incorporation of this instrument into a statistical process control or measurement system. |

| Error alarm: | In the unlikely event of a display overflow or calculation error, an error message is displayed and measurement stops.Measurement cannot continue until the error is corrected. Also, if the battery voltage drops below a certain point, the battery indicator will turn on before measurement becomes impossible, warning the user that the battery needs to be replaced. |

Specifications

| Metric | Inch/Metric | |

| Order No. | 293-100-10 | 293-130-10 |

| Measuring range | 0 – 25 mm | 0 – 1 in |

| Resolution | 0.0001 mm/0.0005 mm (switchable) | 0.000005 in/0.00002 in 0.0001 mm/0.0005 mm (switchable) |

| Maximum permissible error JMPE | ±0.5 μm | ±0.00002 in |

| J MPE | 0.3 μm/0.6 μm | 0.000012 in/0.000024 in |

| Measuring surface | ø3.2 mm | |

| Measuring force | 7 to 9 N | |

| Measuring system | Electromagnetic induction type ABS rotary sensor | |

| Mass | 400 g (440 g with heat shield attached) | |

| Power supply | Lithium battery (CR2032) x 1 | |

| Battery life | Approx. two years when used under normal conditions | |

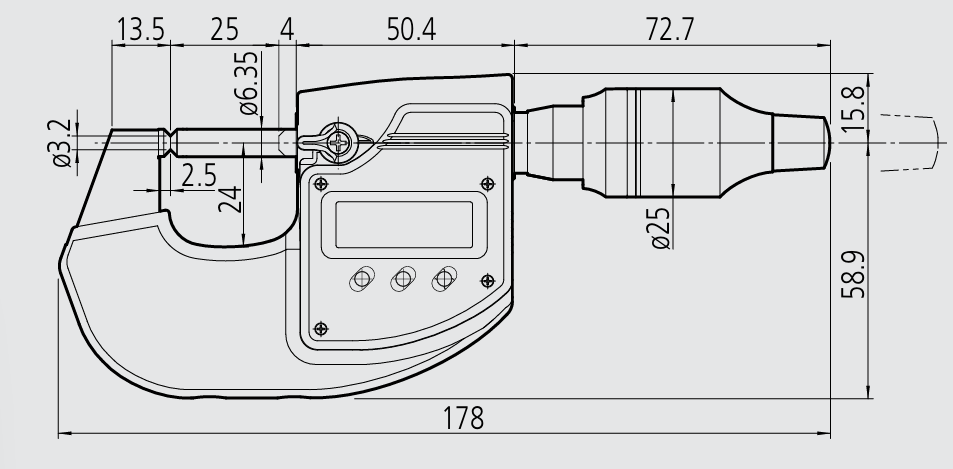

Dimensions